Keep Ahead of Maintenance: Buying Top-Notch Komatsu Undercarriage Parts

Keep Ahead of Maintenance: Buying Top-Notch Komatsu Undercarriage Parts

Blog Article

Efficient Solutions: Undercarriage Parts for Heavy Equipment

Quality undercarriage components play a substantial function in ensuring the smooth operation and durability of hefty machinery. In this conversation, we will certainly explore the value of spending in top-notch undercarriage parts, typical wear difficulties encountered by heavy machinery drivers, the benefits of timely substitutes, standards for selecting trustworthy distributors, and important maintenance ideas to expand the lifespan of undercarriage elements.

Value of High Quality Undercarriage Components

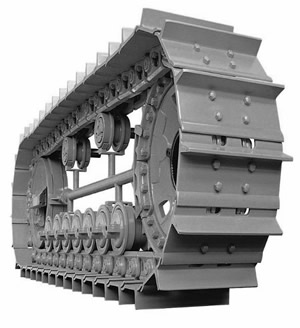

Quality undercarriage components are crucial components in guaranteeing the longevity and efficiency of hefty equipment. The undercarriage of devices such as excavators, excavators, and track loaders plays a crucial function in supporting the device's weight, offering stability on different surfaces, and taking in the effect of unequal surfaces. By purchasing premium undercarriage parts, operators can substantially prolong the life expectancy of their machinery and decrease the threat of unanticipated breakdowns.

One secret advantage of making use of top quality undercarriage components is the improvement of general device efficiency. Sturdy tracks, idlers, rollers, and gears reduce friction and guarantee smoother motion, eventually resulting in enhanced productivity and efficiency on job sites. Dependable undercarriage parts lessen downtime for maintenance and repair services, allowing operators to maximize their operational hours and task due dates.

Common Undercarriage Put On Concerns

Advantages of Timely Replacement

One secret advantage of timely undercarriage component substitute is increased equipment uptime. By changing used parts before they fall short, the threat of unanticipated breakdowns is decreased, reducing downtime for fixings and this website upkeep. This positive technique not just keeps the hefty equipment operational but additionally prevents prospective damage to various other elements that could arise from a stopping working undercarriage.

In addition, replacing undercarriage components without delay can enhance overall performance. A well-maintained undercarriage makes sure ideal device efficiency, permitting smoother procedure and greater effectiveness in completing jobs. This, consequently, results in raised task website efficiency and cost financial savings by preventing hold-ups and disruptions brought on by underperforming machinery. Investing in timely undercarriage part substitute is an aggressive technique that pays off in terms of boosted efficiency and minimized operational costs.

Picking the Right Undercarriage Supplier

Selecting the proper undercarriage vendor is a vital decision that considerably impacts the efficiency and upkeep of hefty machinery. When choosing a distributor for undercarriage components, several factors have to be taken into consideration to make certain optimum performance and cost-effectiveness. A vendor that supplies a large selection of undercarriage components for numerous heavy equipment brands and versions can be helpful as it offers extra choices to meet particular demands.

Moreover, assessing the supplier's customer support and support is vital. A supplier that uses excellent client service, quick response times, and technological assistance can assist decrease downtime and guarantee smooth procedures. Price is also a considerable variable to consider; nevertheless, it needs to my website not be the sole factor. When picking the right undercarriage vendor for hefty machinery, balancing reliability, high quality, and cost-effectiveness is crucial. By carefully assessing these elements, you can select a vendor that satisfies your needs and adds to the reliable efficiency and upkeep of your heavy machinery.

Maintenance Tips for Extended Life-span

To make certain a prolonged life expectancy for hefty equipment undercarriage parts, implementing an aggressive upkeep routine is important. Routinely evaluating undercarriage parts such as track chains, idlers, rollers, and sprockets for wear and tear is critical. Any type of signs of damages or excessive wear should be quickly dealt with to stop more deterioration and possible failures. Additionally, maintaining the undercarriage tidy from dirt, particles, and corrosive products can significantly lengthen its life expectancy. Oiling moving parts according to supplier suggestions aids decrease friction and protect against premature wear. Monitoring track stress and placement is also crucial to avoid irregular wear on the undercarriage elements. Buying quality undercarriage parts from credible providers is similarly important for making certain longevity. By complying with these about his maintenance pointers vigilantly, heavy equipment proprietors can optimize the performance and durability of their undercarriage parts, eventually minimizing downtime and functional costs.

Final Thought

In final thought, high quality undercarriage components are crucial for the effective operation of hefty machinery. Picking a trustworthy vendor and following correct maintenance techniques are essential to guaranteeing the expanded lifespan of undercarriage components.

Excessive wear and tear on undercarriage parts of heavy equipment can lead to substantial operational challenges and increased upkeep costs. Normal examinations, correct maintenance, and timely substitutes of worn undercarriage parts are essential to minimize these typical wear problems and ensure the optimum functioning of heavy equipment.

A provider that offers a vast option of undercarriage parts for numerous heavy machinery brand names and models can be useful as it supplies more alternatives to satisfy particular needs.

By adhering to these maintenance pointers faithfully, heavy equipment owners can maximize the performance and sturdiness of their undercarriage components, eventually reducing downtime and operational prices.

Report this page